The third generation papermaking felt

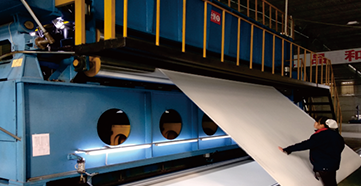

BOM PAPERMAKING FELT

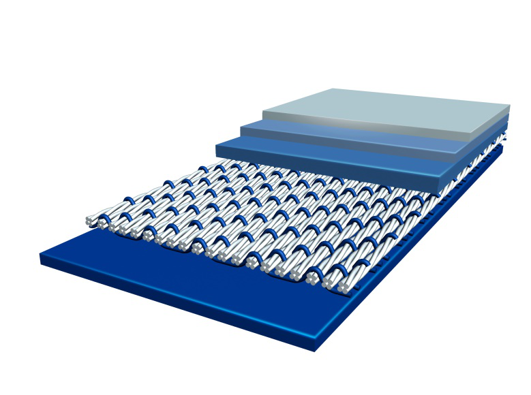

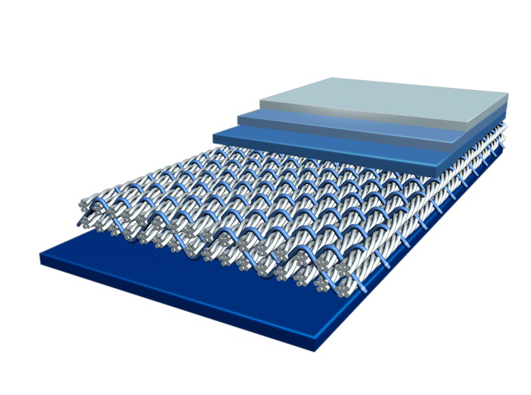

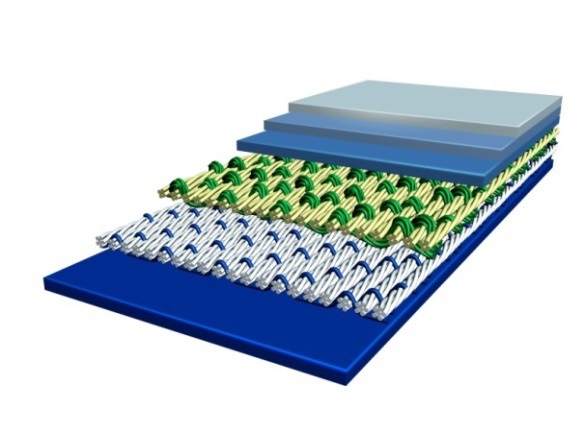

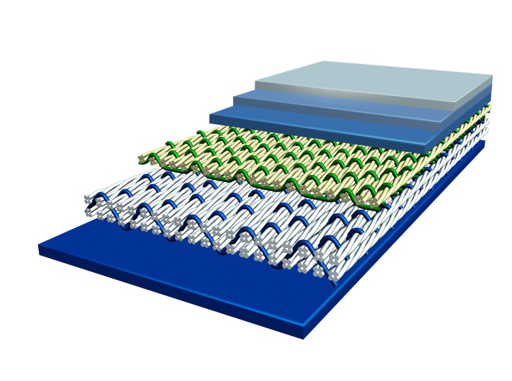

BOM papermaking felt is composed of base mesh layer and fiber layer.It is usually classified according to the structure of base mesh layer,which can be divided into single layer,double layer and laminated BOM papermaking felt.According to the number and type of stacked base mesh,laminated BOM papermaking felts can be divided into 1+1,1+2,2+1,1+1+1,etc.

BOM papermaking felt can meet the needs of various medium and high-speed paper machines.According to the suitable paper types,it can be divided into packaging paperfelt,cultural paper felt,special paper felt, household paper felt,etc.

Note:1 represents single-layer mesh and 2 represents double-layer mesh,which is sorted by the side contacting the paper.

|

|

| SINGLE LAYER BOM FELT | DOUBLELAYER BOMFELT |

|

|

| 1+1 LAMINATED BOM FELT | 1+2 LAMINATED BOM FELT |

Keywords: papermaking felt | press felt

Product message

0395-8662688

0395-8662688

Message

Message